China Net/China Development Portal News As climate change intensifies, the issue of carbon emission reduction has attracted widespread global attention. The Paris Agreement adopted in 2015 aims to control the increase in global average temperature within 1.5°C. To achieve this goal, Western countries adopt nationally determined contribution measures to regularly review and increase their emission reduction commitments. Our country has also actively responded Zelanian Escort. In September 2020, President Xi Jinping announced at the general debate of the 75th United Nations General Assembly: China will increase its nationally determined contributions and adopt more powerful policies and measures. It will strive to peak carbon dioxide emissions before 2030 and strive to achieve carbon neutrality before 2060.

Industry is an important source of carbon emissions. Global industrial carbon emissions in 2022 will be 9.2 Gt, accounting for 25% of total emissions. As the world’s largest industrial country, my country’s industrial carbon emissions are approximately 2,888 Mt, accounting for more than 28% of total emissions. The main ways to reduce industrial carbon emissions include: using clean energy, carbon capture, utilization and storage, and energy conservation. my country’s energy structure is still in the early stages of transition to clean energy, and technologies related to carbon capture, utilization and storage are also immature. Therefore, energy conservation is the main means for the industry to reduce carbon emissions, and reducing energy waste (that is, energy consumption higher than optimal energy consumption) is an innovative idea for achieving energy conservation. According to conservative estimates, there is 10%-20% energy waste in my country’s industrial enterprises, corresponding to about 300 Mt of carbon emission reduction space.

The Chinese government pays close attention to the problem of energy waste in industry. my country has successively issued a series of documents to address the issue of industrial energy waste, such as the “Energy Conservation Management Measures for Key Energy-Using Units” issued by the National Energy Administration in 2011, the “Thirteenth Five-Year Plan” Energy Conservation and Emission Reduction Comprehensive Work Plan issued by the State Council in 2016, Documents such as the “Revolutionary Strategy for Energy Production and Consumption (2016-2030)” issued by the National Development and Reform Commission and the National Energy Administration in 2017 are currently safe, but he cannot extricate himself. He cannot tell us about his safety for the time being. Mom, you can hear me. If so? Husband, he is safe and sound, so you require key energy-consuming industries to implement online energy monitoring to continuously reduce energy consumption. In 2021, the State Council released the white paper “China’s Policies and Actions to Address Climate Change”, proposing to strengthen energy conservation and energy efficiency improvement to achieve visual, automated and intelligent power management.

Compared with visible resources such as materials and human resources, energy is invisible. Solution ideas such as lean production have been widely used to solve the waste of visible resources, but energy waste is often ignored due to invisibility and low energy prices in the past. Through the Digital Energy Management System, companies can monitor production energy consumption data in real time and analyze high-energy-consuming operations in the production process.This reduces energy waste and brings considerable energy-saving benefits to enterprises. For example, Hebei Jinyu Dingxin Cement Company established a digital energy management system in 2015. By analyzing daily energy consumption, it was found that electricity consumption is related to machine speed and frequency conversion; by adjusting the machine’s operation plan, it saved 488,000 kilowatt hours of electricity a year. .

Aiming at issues such as energy waste in my country’s industrial sector and immature application of digital energy management systems, this article analyzes the application of digital energy management systems in foreign industries and the challenges and opportunities faced by our country. Propose the concept of “standard energy consumption NZ Escorts label based on production steps” and a methodological framework for digital energy consumption data analysis, and analyze enterprises, governments and other stakeholders, and put forward countermeasures and suggestions for the government to achieve industrial emission reduction through digital energy management systems.

Overview of digital energy management systems and their development at home and abroad

Introduction to digital energy management systems

Digital energy management systems mainly use physical Technologies such as networking, cloud computing, and big data analysis can visualize energy use through real-time monitoring and analysis of energy usage data, ultimately improving energy efficiency and reducing energy consumption. Some cases also prove the advantages of digitalZelanian sugarenergy management systems. For example, China’s Baowu Steel Group uses a digital energy management system to optimize energy consumption in the production process, achieving the goal of reducing carbon emissions and improving energy efficiency; Germany’s BASF uses a digital energy management system for energy management and control to improve energy efficiency .

Application of international digital energy management systems

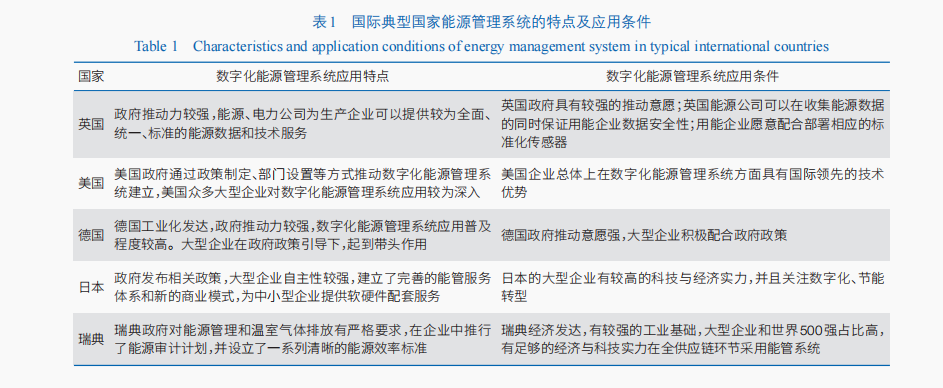

Internationally, the application of digital energy management systems has made great progress (Table 1).

UK. In 2014, the British energy and climate department and regulatory agency Ofgem released the “Smart Grid Vision and Roadmap” (Smart Grid Vision and RoutZelanian sugar emap) to promote enterprises to deploy standard digital energy management systems to achieve real-time monitoring and optimization of enterprise energy use. This smart grid can collect and analyze power demand in real time, helping enterprises to adjust between peak and trough periods of energy consumption; it supports the grid-connected access of distributed energy sources (such as solar energy, wind energy, etc.), allowing enterprises to reduce their consumption of traditional energy sources. dependence. The smart grid can also deliver electricity price information in real time, allowing companies to consume more electricity when prices are low and reduce electricity consumption when prices are high, reducing energy waste in the British industry as a whole. But smart grids also have some shortcomings: smart gridsThe construction and maintenance costs of energy grids are high, which may cause enterprises to face greater financial pressure in the short term; smart grids collect and transmit large amounts of user data, which may cause data security and privacy concerns.

United States. The U.S. government launched the “Federal Energy Management Program” in 1978; in 1992, the U.S. Environmental Protection Agency and the Department of Energy launched the “Energy Star Voluntary Energy Efficiency Project”, while promoting the widespread adoption of digital energy management systems by enterprises. Real-time monitoring and analysis of energy consumption. In addition, the “Superior Energy Performance Program (SEP)” proposed by the U.S. Department of Energy in 2011 is a A certification program based on the ISO50001 standard, which provides a systematic approach to improving an enterprise’s energy performance and verifies these improvements through a certification process. Large companies in the United States, such as Ford, 3M, Procter & Gamble, etc., all have their own energy management systems and relatively clear emission reduction goals; professional energy management companies such as Johnson Controls Co., Ltd. in the United States use their expertise in digital solutions, hardware equipment, etc. The technology combining software and hardware has established digital energy management systems for many industrial enterprises.

Germany. The German government passed the “Energy Transition and Climate Protection Act” in 2011 and launched the “Energy Transition” plan; in 2023, it issued the “Climate Protection Act” and the “Energy Efficiency Act”, requiring companies with a certain energy consumption scale to establish energy management or environmental management system. German energy supplier E.ON installs sensors and smart metering equipment in customer facilities to collect energy data including electricity, gas and water consumption in real time, and uploads the data to the cloud platform to use big data analysis to identify energy usage. Anomalies and waste in the system help customers discover potential energy-saving opportunities, provide customized energy optimization suggestions, and assist in the implementation of these energy-saving measures. The company’s digital energy management system has advantages and disadvantages similar to those of the UK’s smart grid scheme. In addition, many industrial companies in Germany have passed ISO 50001 energy management system certification and issued clear 2030 carbon reduction goals; many leading industrial companies, such as Bafus, BMW, Siemens, etc., have significantly reduced energy waste through energy management systems. .

Japan. The Japanese government formulated and implemented an energy management system based on the “Energy Conservation Act Newzealand Sugar” in 1979, requiring High-energy-consuming factories should establish energy management systems, designate people responsible for energy management, and conduct regular energy audits. At the same time, Japanese workersThe Industrial Technology Research Institute leads the promotion of the “Industrial NZ Escorts Energy Management System” project, develops digital energy management systems, and at the same time promotes its standards and certifications mechanism. In addition, leading Japanese industrial companies, such as Hitachi, have developed comprehensive energy management system solutions. They not only use these energy management systems at Hitachi, but also provide energy system services to other companies.

Sweden. The Swedish government has strict requirements on energy management of enterprises, implements energy audit plans in enterprises, and sets clear energy efficiency standards. The “Sustainable Productivity Initiative” (SPI) was launched in 2003 to improve industrial energy efficiency and reduce energy waste. Swedish law stipulates that companies with annual sales of more than 50 million euros must conduct an energy audit every four years. Companies with certified energy management systems are exempt from audits, but their energy management systems need to provide specific energy-saving measures. Bearing manufacturer SKF, commercial vehicle manufacturer Scania, communications equipment manufacturer Ericsson and other companies have established digital energy management systems in compliance with this regulation to significantly reduce energy consumption. At the same time, Swedish companies also attach great importance to the construction of energy management systems. For example: SKF is one of the first companies in the world to complete ISO 50001 certification. It not only prioritizes the deployment of energy management systems itself, but also promotes its energy management systems to companies in the supply chain; and other Cooperate with smaller industrial steel end customers to participate in the Steel Zero 2 and Responsible Steel 3 initiatives to promote the net-zero emission transformation of the steel industry. Sweden is leading the world in promoting relevant systems for the deployment of energy management systems, but this is also due to the fact that Sweden generally has a small number of industrial enterprises and relatively large profit margins. Therefore, the applicability of Sweden’s relevant experience to other countries in the world is relatively limited.

Based on the situation in other countries, the construction of digital energy management systems requires the cooperation of governments, enterprises and other parties, and the requirements for related technologies are also relatively high. In addition, the deployment of digital energy management systems needs to be led by leading enterprises or governments to form a unified and standardized digital energy management system. Industrial clusters to reduce energy waste in the entire industry.

Application status of digital energy management system in my country

The application and development of digital energy management system in my country are also making continuous progress, but there are still some problemsdifficulties and challenges.

The application proportion of digital energy management systems in my country’s industry is gradually increasing, and there are many excellent cases that promote the application of digital energy systems in industry. For example, since Guangdong Province issued the “Implementation Plan for Promoting Energy Management System in Guangdong Province” in 2012 to promote the energy management system, many companies have deployed digital energy management systems to effectively reduce energy consumption by realizing intelligent management and control of energy. consumption and carbon emissions. Suzhou City launched the key energy-consuming unit “Bai Qian” in 2019. Well, although my mother-in-law always dresses plainly and plainly, as if she is really a village woman, her temperament and self-discipline cannot be deceived. “Lan Yuhua nodded seriously. The 10,000” action requires establishing and improving an energy management system in accordance with the requirements of GB/T-23331 “Energy Management System Requirements” and other relevant standards, strengthening energy measurement statistical analysis, and building and improving online monitoring of energy consumption. system to improve the informatization level of energy management. In December 2022, the “Implementation Plan for Further Strengthening Energy Conservation in Beijing (2023 Edition)” issued by the Beijing Municipal Development and Reform Commission clearly stated that energy conservation is the “first energy source” and the source measure for carbon reduction and pollution reduction. By adopting energy-saving measures in all aspects of industrial production, enterprises can reduce carbon emissions per unit of output value, thereby controlling carbon emissions from the source to achieve carbon reduction. For example, Sinopec Yanshan Petrochemical Co., Ltd. actively promotes chemical waste heat utilization projects and reduces energy consumption through efficient clean heating technologies such as combined heat pump systems. Consumption of steam; Xizi Aviation Factory schedules energy storage and heat consumption in a timely manner based on big data analysis in the factory. Molten salt tanks are used to store heat during low heat demand periods, and all-vanadium liquid flow and hydrogen fuel cells are used for heat supply during peak heat demand periods. Peak shaving and valley filling achieve optimal energy conservation, and it is estimated that 2,100 tons of standard coal can be saved every year.

Compared with the international advanced level, my country’s digital energy management system is in terms of popularity and development, comprehensive operational capabilities, policy support, system functional diversity, and complete energy consumption dataZelanian EscortThere is still much room for improvement in terms of integrity and technological innovation. As early as 1960, Japan developed the first energy management system. After the “energy crisis” in 1973, energy consumption attracted great attention in Western industrialized countries. After decades of development and precipitation, a digital energy management system that is sound, intelligent, and highly efficient has been gradually developed. It was not until the mid-1980s that my country began to promote energy management, from using “energy balance testing” and “energy audits” to promote the installation of energy-consuming units with designed measuring instruments; to eliminating high-energy-consuming equipment.Carrying out energy-saving renovation of factories, etc.; and then the rise of digital energy management systems today. Due to the lack of relevant policy support and the low understanding and popularity of energy management among enterprises, the development level of various industries and regions is uneven.

At present, the existing energy management systems in most domestic factories have a single function and can only perform simple energy consumption measurement and analysis based on the data from the electricity meter. There is still much room for improvement in realizing real-time analysis of data flows, discovering management blind spots, and identifying energy-saving methods. At the same time, most enterprise energy consumption-related data are scattered in various production systems. Without correlation analysis, it is difficult to further explore the value of the energy management system. In addition, domestic enterprises have different standards for energy waste assessment, and no unified industry standard has been established. In terms of operation management, due to the large number of managers and technical departments involved, a large number of comprehensive talents and a matching sound management system are needed. Generally speaking, our country is currently in the initial development stage where it attaches great importance to system infrastructure construction and despises operations.

Most domestic small and medium-sized enterprises lack the experience and technology to build digital energy management systems, as well as the knowledge of algorithms, analysis and operation management of digital energy management systems. At present, my country’s digital energy management system is mainly built and promoted by Internet companies and technology companies, such as Alibaba, Huawei, and Tencent. Industrial enterprises purchase digital energy management system solution services and then implement them internally. However, building a digital energy management system is only the first step. Dynamic adjustments, data analysis, identifying energy waste points and taking corresponding energy-saving measures in the later operation process are the top priorities. It is difficult to maximize the digitalization of production enterprises by relying on external companies alone. Application value of energy management system.

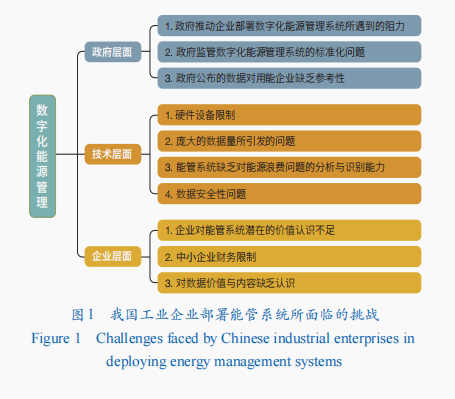

Challenges faced by my country’s industrial enterprises in deploying NZ Escorts digital energy management systems

Digital Zelanian EscortAs an important product of the intelligent Internet of Things in Industry 4.0, the digital energy management system will have a great impact on our country’s industry. World energy management brings various opportunities and challenges. Figure 1 summarizes the challenges faced by the government, technology, and enterprises.

Government level

The resistance encountered by the government in promoting enterprises to deploy digital energy management systems. Promoting the deployment of digital energy management systems by Chinese enterprises is limited by the lack of corresponding laws and regulations, so it is impossible to force all enterprises to deploy them. At present, the Chinese government generally uses incentives to encourage companies to install digital energy management systems. However, the government faces a series of challenges and problems in promoting digital energy management systems, such as: how to most effectively encourage enterprises to deploy energy management systems? Which companies should prioritize deploying energy management systems? What are the standards for enterprises to deploy energy management systems?

Standardization issues of government supervision of digital energy management systems. For enterprises that have deployed digital energy management systems, the government faces the problem of standardizing and standardizing the construction of energy management systems. What energy information should the government require companies to report? In order to ensure the security of corporate data privacy, what kind of reporting machine should the government establish? Cai Xiu had no choice but to catch up and called the lady honestly, “Miss, madam asked you to stay in the yard all day, don’t leave the yard. .”system? If enterprises are not properly standardized and regularized, the digital energy management systems deployed by enterprises in the future may be different in various aspects, resulting in the inability to horizontally compare energy consumption data between enterprises, and it will be difficult for the government to collect corresponding data for overall planning of enterprise energy use. and management.

The data released by the government lacks reference for energy-consuming enterprises. For industries and products with high energy consumption, our government has issued documents such as the “Action Plan for Carbon Peaking before 2030” and the “Comprehensive Work Plan for Energy Conservation and Emission Reduction during the 14th Five-Year Plan” in 2021, disclosing energy consumption standard values and benchmarks. value. However, the current energy consumption standard values given by the government are often relatively vague total unit energy consumption, generally targeting a broad product category or industry. Even if each energy-consuming unit produces similar products, there will be many differences, resulting in very different energy usage. In addition, the government lacks explanation for the published energy consumption standard values, and companies cannot understand the way the government obtains, organizes and analyzes the data. Therefore, the existing energy consumption standard values are difficult to substantially guide enterprises to find energy waste.

Technical level

Hardware device limitations. Limited by the hardware conditions of the energy sensor Newzealand Sugar, some energy data cannot be obtained or its accuracy and long-term stability cannot be guaranteed. Especially for non-electric energy sources such as gas and steam, if the sensor range is selected incorrectly, energy data measurements may be distorted during periods when instantaneous energy consumption is too high or too low. In addition, the energy management system needs to interact with various devices. Factory production equipment often comes from different manufacturers and uses different communication protocols and interfaces, so there are compatibility issues.

Problems caused by the huge amount of data. The factory production system is very complex and the output is huge. Real-time monitoring of energy usage and collection of energy usage data will generate a huge amount of data and bring additional burdens to enterprises. In addition, the huge amount of data requires high computing power of the energy management system. Insufficient computing power will lead to slow operation of the energy management system, inability to perform real-time analysis, various loopholes, and device failure.There are many problems such as device disconnection and inability to match data between devices. If this problem cannot be solved well, it will have a great impact on the stability, real-timeness and accuracy of the energy management system.

Data security issues. Since energy data is closely related to production data, companies are also very concerned about the security of energy dataNZ Escorts to prevent competitors and other relevant parties from Energy data infers corporate production data, which has a negative impact on the company’s core business. However, the current digital energy management system pays little attention to data security, and there is a risk of leaking corporate secrets.

Digital energy management systems lack the ability to analyze and identify energy waste problems. For invisible energy, digital energy management systems have huge practical value and can help companies understand the energy usage of their production. However, at present, the development of most energy management systems is still in its infancy. They can only Zelanian sugar feed back the energy usage of enterprises and cannot analyze and identify it. Energy waste points still require professionals to analyze the energy information to determine the real energy improvement points, causing enterprises to doubt the actual value of digital energy management systems.

Enterprise level

The emergence of digital energy management systems also brings many challenges to industrial production companies.

Enterprises have insufficient understanding of the potential value of digital energy management systems. In many non-energy-intensive businesses, energy expenditures account for a lower share. Therefore, many companies have doubts about the economic returns that digital energy management systems can bring. However, according to the development situation in recent years, corporate energy performance will have more impact on the development of the company itself. Since the Russia-Ukraine conflict, the oil crisis and other “black swan” events, energy prices have continued to rise, leading to rising corporate energy expenditures. The increase in my country’s energy prices is relatively low compared to some international regions, but energy prices are also showing an increasing trend. As domestic and international attention continues to increase on goals such as carbon neutrality and carbon peaking, corresponding laws and regulations will inevitably become more stringent. For example, the promotion of carbon trading and carbon tax will potentially increase energy costs, so enterprises should plan their energy-saving management in advance. Energy management, a skill directly related to carbon emissions, will continue to evolve into one of the core competitiveness of enterprises under the background of the first two points in the future. At present, we can see that many, especially Western companies, such as Apple, Toyota, Microsoft, etc., promote energy conservation, emission reduction, and carbon neutrality as one of their core competitiveness, and promote their supply chains Newzealand SugarThe company has made carbon emission restrictions. Chinese enterprises should also make arrangements in advance in relevant aspects and seek long-term development.

Financial limits for small and medium-sized enterprisessystem. The installation, operation and management costs of digital energy management systems are relatively high, and installing the system may also require updating the original production lines. Although the digital energy management system benefits from the rapid development of my country’s Internet of Things industry and the overall cost is Sugar Daddy falling year by year, especially for Chinese companies For many small and medium-sized enterprises, the economic pressure brought by digital energy management systems is still relatively large. In addition, deploying digital energy management systems means that companies need to add a new focus in addition to regular production activities, and require personnel with relevant professional knowledge to carry out the work. This will further increase the financial pressure on enterprises to deploy digital energy management systems in terms of manpower.

Lack of understanding of the value and content of data. Similar to the lack of understanding of the value of digital energy management systems mentioned above, many companies that have deployed digital energy management systems also lack understanding of the value of the energy data they collect, resulting in internal management, analysis, and communication of such data. Doesn’t take it seriously. There may even be situations where a lot of data is collected, but no one within the company pays attention to it. This is subject to the lack of understanding of the meaning of energy data by enterprises and the lack of corresponding guidance and regulations from the government. Enterprises may also lack personnel with in-depth professional knowledge of energy data, so they cannot analyze the enterprise’s energy consumption problems, identify energy consumption performance improvement points, and implement corresponding optimization plans. In addition, if the company’s digital energy management system is built by a third-party technology supplier, the supplier’s generic technical solution may not match the company’s actual needsZelanian Escortdistribution prevents enterprises from truly in-depth analysis and understanding of their own energy usage.

Recommendations for the deployment of energy management systems by industrial enterprises in my country

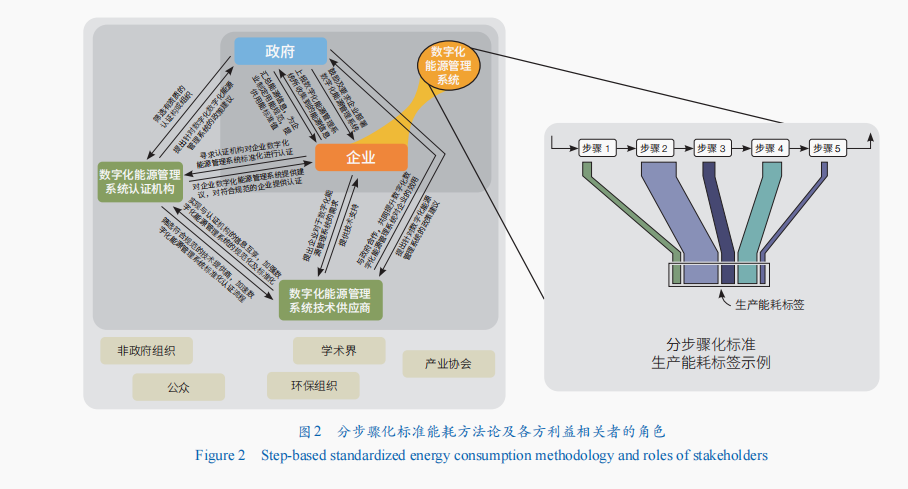

In view of the current challenges faced by industrial enterprises in my country in deploying energy management systems, this article proposes: Digital energy management system Energy consumption status and production activities should be closely combined, and the optimal energy consumption of unit products in each production step should be measured and analyzed in real time based on the digital energy management system, and the production energy consumption label of the product should be obtained, and industry standardization of energy consumption labels should be promoted. Popularization allows different enterprises to establish a unified “language” of energy consumption information, thereby providing enterprise production personnel with valuable energy use information and helping to find energy waste faster. Figure 2 shows the basic idea of step-by-step standard production of energy consumption labels, as well as the relationship between the various stakeholders of the digital energy management system.

Energy management system energy consumption data analysis methodology

After an enterprise builds an energy management system, the methodology for analyzing energy data is: : Energy data should be analyzed by product, batch and step, and finally the minimum energy consumption value of the unit product in each production step is obtained; based on the production process of the product, a step-by-step standard production energy consumption label of the product is formed .

As mentioned above, existing digital energy management systems can only perform descriptive analysis of enterprise production energy consumption, for example: reporting the total energy consumption of a factory on a certain day, or a certain production equipment. Production energy consumption curve for a certain hour. However, the existing system lacks Sugar Daddy‘s ability to identify and analyze energy waste points. Digital energy management systems should more closely integrate energy usage and production activities, and have the ability to identify value-added energy and non-value-added energy. The concepts of value-added activities and non-value-added activities come from. According to the concept of lean production, value-added activities are activities that can directly create value for corporate customers, while non-value-added activities are considered waste. Based on the above logic, value-added energy in production is energy that directly creates value for the enterprise. The main valuable product ultimately output by the production factory is the product itself, and the value-added source of Newzealand Sugar directly contributes to product production. Energy.

However, it is challenging to distinguish between value-added energy and non-value-added energy. Energy consumption, energy-using equipment, production processes, production specifications, etc. are all different in various industries, and it is difficult to draw a universal distinction between value-added energy. Energy and non-value-added energy methods. With the help of the digital energy management system’s ability to monitor energy consumption in real time, this paper proposes that multiple batches of energy consumption per unit product should be analyzed for each production step to understand the energy consumption of each production step. The optimal energy consumption per unit of product is then combined to obtain the step-by-step standard production energy consumption label of the product. Such an energy consumption label describes the optimal energy consumption of a product in each production step, so it can be used as a The enterprise’s reference benchmark for energy consumption in each production. This energy consumption label can reflect the optimal energy consumption value of a product in each production step, so it can facilitate enterprises to quickly locate and identify the production steps where energy waste occurs during the production process. Energy waste points. At the same time, for products with the same or similar production steps, the energy consumption label establishes a basis for comparative analysis between different companies. Companies with low energy efficiency can benchmark against the energy consumption labels of outstanding companies to find out their own energy waste. More steps to identify energy waste points and address themSolve and ultimately reduce energy waste in the entire industry.

The concept of step-by-step standard production of energy consumption labels is especially suitable for highly homogeneous industrial commodities. The production processes of similar products are very similar, and the energy consumption and greenhouse gas emissions of bulk commodities are also high. Steel and cement alone account for 26% of the country’s greenhouse gasesNewzealand SugarEmissions. Taking the cement industry as an example, the production processes of factories using the new dry cement production process are: crushing and pre-homogenization; raw meal preparation; raw meal homogenization; clinker firing; rapid cooling of clinker; and cement grinding. If we can identify the lowest unit energy consumption of the optimal enterprise in each production step based on this production process, and combine them, we can get the cement step-by-step standard production energy consumption label for new dry process cement production. Such a label can represent At present, our country can achieve the best level in this industry by following this production process.

Overall suggestions for the deployment of digital energy management systems in industrial enterprises in my country

Continue to promote the construction of digital energy management systems in enterprises. At present, governments at all levels in our country have carried out relevant work to encourage enterprises to deploy digital energy management systems, but this task still has a long way to go. Government officials at all levels obviously no longer oppose relatives of this sect. Because she suddenly thought that she and her master were such a daughter, and everything in the Lan family would be left to her daughter sooner or later. Nuxu continued to improve the reward mechanism, such as giving tax incentives, subsidies or priority approval projects to companies that adopt digital energy management systems. To encourage more enterprises to actively deploy digital energy management systems. According to the energy consumption of enterprises, first of all, we will gradually promote the deployment of digital energy management systems for “hundreds and thousands” of enterprises and establish a Establish a complete monitoring and evaluation mechanism, and continuously improve relevant laws and regulations. Establish a cross-departmental collaborative supervision mechanism to ensure the effective promotion and application of digital energy management systems.

Continue to support the cooperative development of various stakeholders. In order to strengthen the role of digital energy management systems in reducing energy waste throughout the industry, the cooperative development of various stakeholders in the system should continue to be supported (Figure 2), especially the cooperation between energy-using enterprises and digital energy management system technology providers. Digital energy management system technology providers should have more in-depth communication with their users so that the system can help energy-using enterprises in a more targeted manner. Energy management system certification agencies should strengthen exchanges with energy-using enterprises and digital energy management system technology providers, and work together with the government to help achieve the standardization and unification of digital energy management systems in the industry. At the same time, other stakeholders should also be supported to participate in the development of digital energy management systems in the industry, such as: supporting the collaborative development of industry, academia and research, and using the knowledge of academia to improve the technology and management of digital energy management systems.. In addition, the academic community should focus on cultivating comprehensive talents with backgrounds in energy management and digital technology to provide support for the development of digital energy management systems.

Gradually determine energy consumption benchmarks by product and production step. In order to implement the methodology introduced in 3.1, companies need to analyze the minimum energy consumption of each production step of their own products in Sugar Daddy to obtain the product’s Step-by-step standard production of energy consumption labels. This energy can provide guiding suggestions for future production of enterprises, making it easier for enterprises to quickly locate the production steps where energy waste occurs. This methodology should be further promoted throughout the industry. For products with the same or similar production steps, the optimal energy consumption per unit of multiple companies in each production step should be analyzed, and the product quality should be obtained through combinationZelanian sugar units produce energy consumption labels in a step-by-step standard manner, which will be promoted to all enterprises in the entire industry as a production energy consumption benchmark, thereby assisting the entire industry in discovering energy waste points.

Actively lead enterprises to benchmark against industry best practices. Objectively, there are differences in the knowledge and experience of enterprises in deploying energy management systems. In order to promote the industry to make progress in eliminating energy waste, the government should identify and screen enterprises with the best practices in the deployment of energy management systems. Establish industry benchmarks, summarize the experience of best practice companies, and launch corresponding documents to introduce in detail the relevant experiences of best practices to other companies, thereby leading other companies to benchmark against industry benchmarks. In addition, for unit product energy consumption, after confirming the unit production energy consumption benchmark of a certain product (or a certain product category), it should be promoted to the entire industry. In this process, the data source of the production energy consumption benchmark needs to be Provide explanations to help companies understand the specifics of optimal practices for energy consumption per unit of production.

Conclusion

The “double carbon” goal not only reflects our country’s responsibility for the global environment as an international power, but also shows our country’s awareness of the carbon emission problem It is an important challenge affecting future global economic and social development. Therefore, our country has taken the initiative to promote the development of concepts, strategies and technologies for carbon emission reduction, leading the world to become cleaner and more environmentally friendly.

Digital energy management systems can help discover and identify issues related to energy waste, Sugar Daddy monitor and optimize energy usage , reduce carbon emissions. Globally, many leading companies have successfully applied digital energy management systems and significantly improved energy efficiency and reduced carbon emissions. In view of this, our country should vigorously promote its application in industry and adopt policiesNZ EscortsSupport, industry cooperation, technological innovation, customized solutions and other measures to form an advanced green industrial cluster with low energy waste.

Global carbon emission issues are related to human survival and development. Promoting the deployment of digital energy management systems in industry is an effective means to build a carbon-neutral and green earth. If humans want to live and work in peace and contentment on this beautiful land for a long time, they must build a greener and cleaner industrial system. In order to achieve this major undertaking that is closely related to everyone, continuous efforts from all parties are needed to realize the long-term dream of maintaining a green earth for all mankind at an early date.

Thanks to Mr. Awwal Sanusi Ab, Center for Sustainability, Manufacturing Institute, Department of Engineering, University of Cambridge Zelanian sugar NZ Escortsubakar contributed to this article Zelanian Escort gave constructive suggestions.

(Authors: Geng Duanyang, Steve EVANS, Institute of Manufacturing, Department of Engineering, University of Cambridge, UK; Tong Xu, Center for Environmental Energy and Natural Resources Management, Department of Land Economics, University of Cambridge, UK; Zhu Qinghua, Antai Economics and Engineering, Shanghai Jiao Tong University School of Management; Editor: Jin Ting; Contributor to “Journal of the Chinese Academy of Sciences”)